NEWSLETTER

Sign up for GMORS latest news.

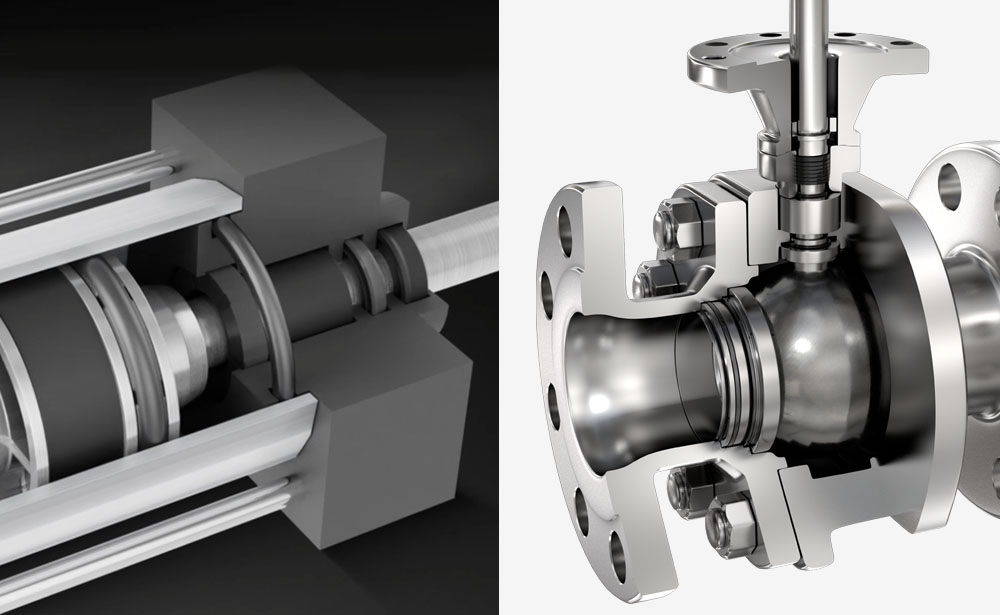

O-Rings are indispensable sealing components widely used in industrial and everyday applications, such as machinery, pipeline systems, automobiles, and electronic devices. Their primary function is to effectively prevent fluid or gas leakage, ensuring stable operation of equipment. However, the process of selecting the right O-Ring is complex, requiring consideration of multiple factors, including material, size, working environment, and pressure conditions. Improper selection can shorten equipment lifespan and result in production downtime and increased costs. This article provides 9 professional tips to help you select the right O-Ring, improve sealing performance, and reduce the risk of failure.

1.1 Differences Between Static and Dynamic Sealing

It is essential to distinguish the type of O-Ring application:

1.2 Determine Working Conditions

Consider the following working conditions:

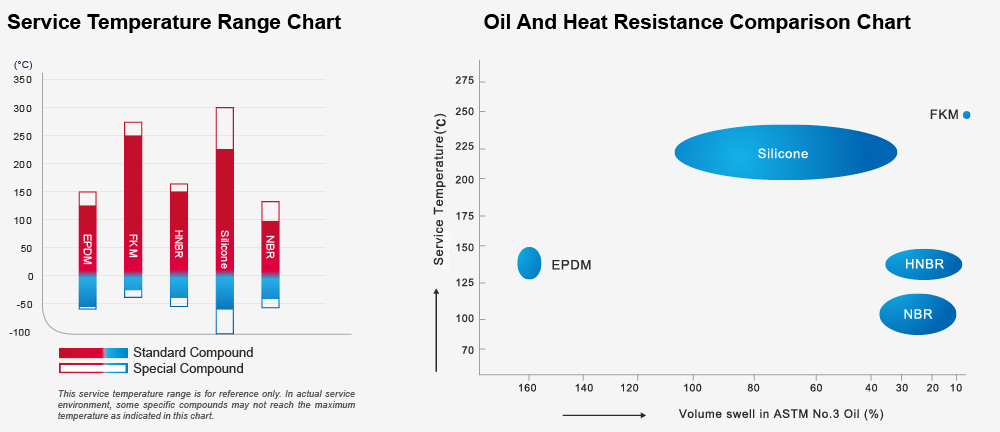

2.1 Analysis of Common Materials

Various materials are suitable for different working environments:

2.2 Material Application Recommendations

2.3 Avoiding Mismatched Materials

Using mismatched materials may result in:

3.1 Measurement Methods

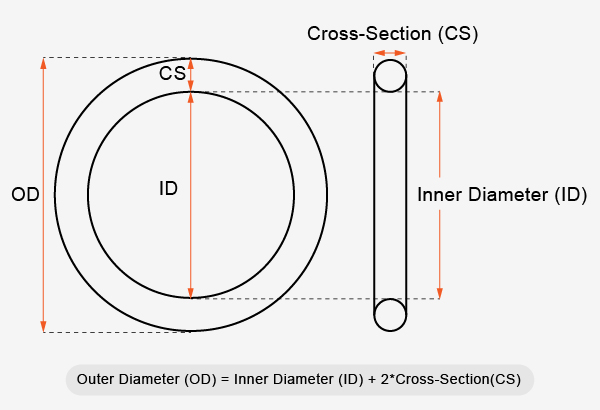

Precisely measure three key dimensions of the O-Ring:

3.2 Size and Groove Compatibility

The O-Ring's size must match the groove dimensions, with a recommended compression ratio of 10%-30% to maintain proper sealing performance.

3.3 Importance of Tolerance

Tolerance control is critical:

4.1 High-Temperature Environments

For high temperatures up to 200°C, FKM or Silicone is recommended for reliable performance.

4.2 Low-Temperature Environments

NBR or Silicone performs well in low temperatures, withstanding conditions as low as -50°C. For even lower temperatures, contact our team for customized solutions.

4.3 Effects of Temperature Fluctuations

Frequent temperature changes can accelerate hardening and cracking, leading to sealing failure.

5.1 Pressure Requirements for Static Sealing

Static sealing demands O-Rings with high resistance to compression deformation to maintain long-term effectiveness.

5.2 Pressure Requirements for Dynamic Sealing

For dynamic applications, materials with low friction and high wear resistance are necessary to extend service life.

5.3 Recommendations for High-Pressure Environments

Use HNBR or FKM in high-pressure scenarios to ensure that the O-Ring resists deformation and rupture.

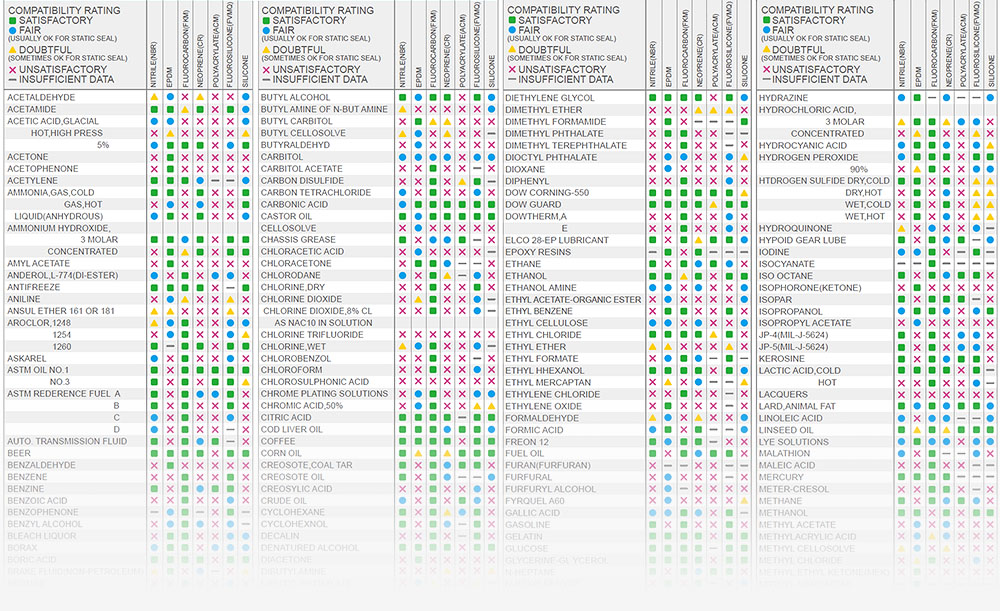

6.1 Effects of Chemical Corrosion

For applications involving strong acids, alkalis, or organic solvents, PTFE or FKM should be used to prevent corrosion.

6.2 Special Requirements for Food and Medical Industries

FDA-compliant Silicone or EPDM materials are essential for ensuring safety and hygiene in food and medical applications.

6.3 Avoiding Chemical Reactions

Mismatched materials may cause chemical reactions, such as swelling, cracking, or failure, compromising the seal.

7.1 Wear Resistance in Dynamic Applications

For high-speed or reciprocating motion, choose materials with excellent wear resistance to enhance durability.

7.2 Impact of Friction Coefficient

Using internal lubrication formulas effectively reduces friction, extending the O-Ring's lifespan.

7.3 Regular Wear Inspection

Inspect O-Rings periodically for wear and replace them promptly to prevent leaks.

8.1 Preventing Damage During Installation

Use professional tools to avoid cutting or tearing the O-Ring during installation.

8.2 Importance of Lubrication

Applying lubricants during installation reduces friction and minimizes the risk of damage.

8.3 Ensuring Correct Installation

Verify that the O-Ring is fully seated in the groove without deformation or twisting.

9.1 Regular Inspection and Replacement

Check the O-Ring regularly for aging or wear and replace it based on usage frequency.

9.2 Storage Environment

Store O-Rings in a cool, dry place away from direct sunlight, high temperatures, and moisture to prevent material degradation.

9.3 Addressing Issues Promptly

Replace damaged or leaking O-Rings immediately and ensure correct installation.

Selecting the right O-Ring is critical to achieving effective sealing. It requires careful consideration of factors such as material, size, temperature, pressure, and chemical environment. By following these 9 professional tips, you can choose the ideal O-Ring, enhance sealing performance, and extend equipment lifespan. Whether for static or dynamic applications, proper selection and regular maintenance significantly reduce the risk of sealing failure and ensure stable equipment operation.

GMORS, as a professional rubber sealing manufacturer, brings years of expertise and high-quality products to offer tailored O-Ring solutions for various applications. We can meet your specific requirements for temperature, pressure, and chemical resistance. Let GMORS be your trusted partner in enhancing equipment efficiency and minimizing operational risks.

Sign up for GMORS latest news.

Copyright ©GE MAO RUBBER INDUSTRIAL CO., LTD. All rights reservedTerms and Conditions|Privacy policy