NEWSLETTER

Sign up for GMORS latest news.

GMORS provides several solutions for low friction solution to elastomeric seals. One of the highly interested techniques is the PTFE coating. It is a dry film reducing surface friction of seals without use of fluid lubricant. Providing numbers of advantages to assembly line, GMORS advanced PTFE coating process give you the qualified and reliable seals coating.

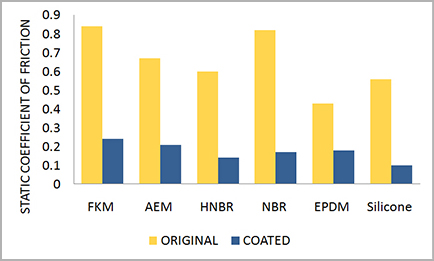

With GMORS PTFE coatings, no matter which rubber material is, the static coefficient of friction can be reduced over 70% as shown in Figure 1.

A micron-thick coating changes the surface properties and helps prevent the stick-slip phenomenon. The improved friction characteristics benefit a lot in automated/manual assembly line, like avoiding sticking, twisting or even tearing of seals. Easy assembly also enhances the production efficiency. In addition, with color added, it helps identification of similar parts to prevent mix-up.

In GMORS's coating process, we dedicate to provide a functional coating without negative influence to sealing characteristics. To better define and fit customer's needs, we examine coatings in several aspects, such as endurance to heat and chemicals, thickness, assembly easiness or cleanliness. Our lab professionals carefully conduct various experiments and strict verifications with innovated technologies to bring our customers the best coating solutions.

Oil Immersion and Heat Aging

The coating has to be able to withstand specific environment and service conditions for customer's applications. Thus, better endurance to heat and chemicals become one of our testing focuses. By creating similar usage environments to customer's needs, PTFE coatings are tested and showing great improvement on chemical resistance and thermostability with our new-released coating techniques.

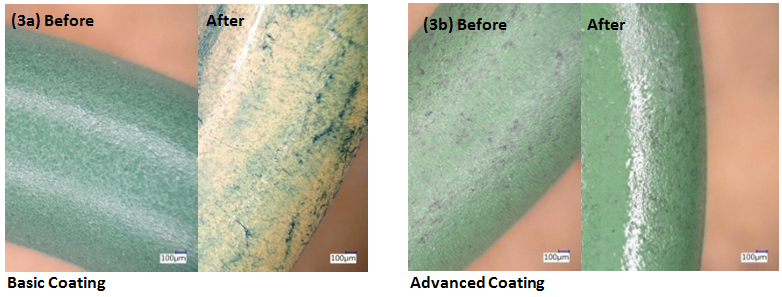

As shown in Figure (3a) PTFE-coated seal is immersed in a sample fluid and facing serious color changed. However, with advanced PTFE coating techniques, like (3b) ,the seal will remain the same appearance after immersion.

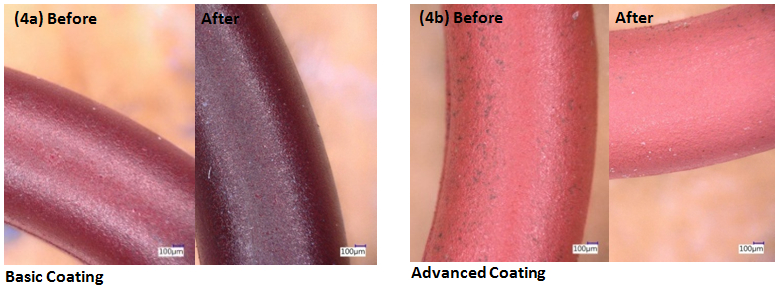

Besides, Figure (4a) shows that basic coating was seriously damaged with dramatic color change after heat aging test. On the other hand, no color change is observed with the advanced PTFE coating techniques Figure (4b). The heat resistance is enhanced.

Assembly Simulation Experiment

When focusing on the coating status during assembly, good adherence of coating to the seal surface with no apparent cracking or peeling is expected. Therefore, we carry out an assembly simulation experiment to primarily examine the coating adhesion.

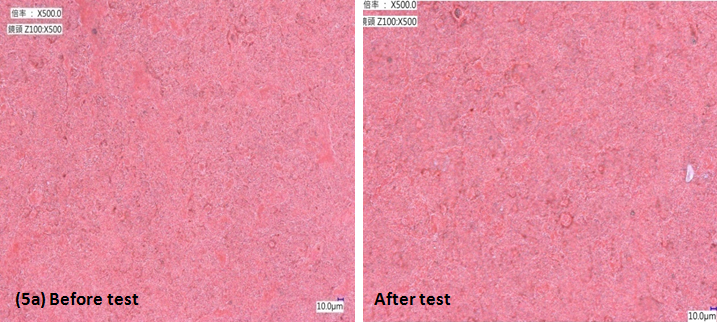

We stretch the specimen to 100% elongation for 10 cycles, and then observe specimen under microscope with 500x magnification. No cracks or damage is observed in GMORS advanced coating, as shown in Figure (5a).

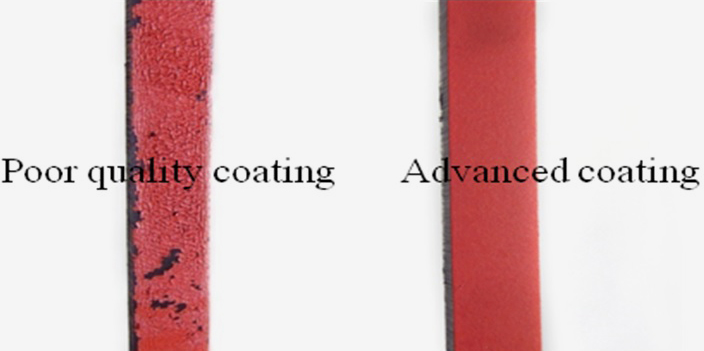

After 10 cycles of 100% elongation stretching, results comparison of advanced coating and poor quality coating is shown as Figure 6. Serious damage is observed in poor coating while advanced coating remains its completeness.

Cleanliness

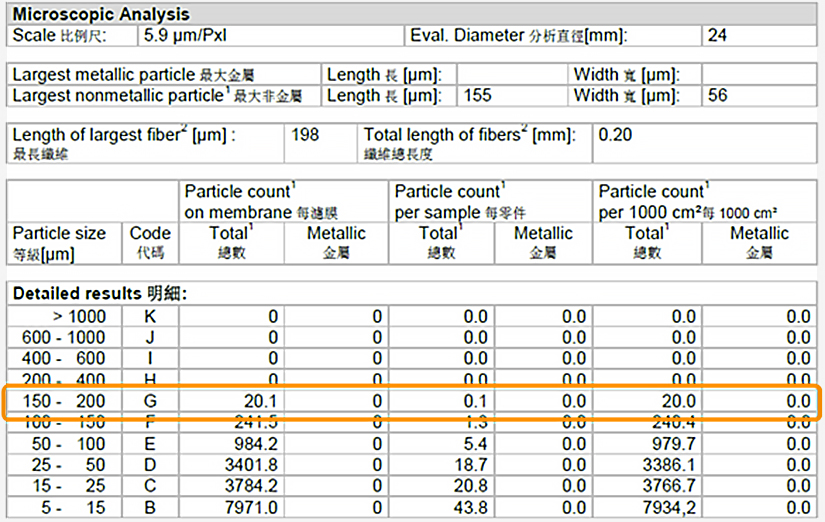

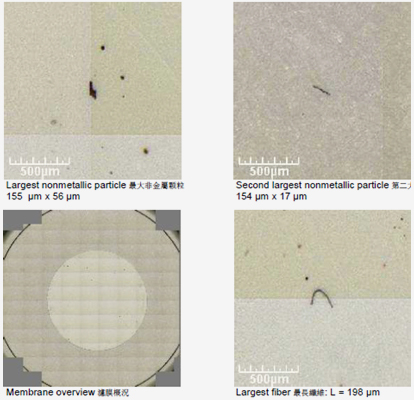

Monitoring technical cleanliness becomes a critical must-be these days in more and more high-end industries. PTFE coating is a dry film above rubber seals which saves customers from fluid lubricant pollution concerns. However, to put it straightly, many external factors may still lead to coating particles. These fractures may pollute the surroundings and it is what GMORS prevent from.

Based on the assembly simulation test, GMORS advanced coating can meet most of cleanliness requirement of automotives OEM markets: Grade G6 in ISO 16232[1]

[1] An expected value of cleanliness which will require further test for each occasion.

Cleanliness Analysis Report of coated seals according to ISO 16232

Thickness measurement

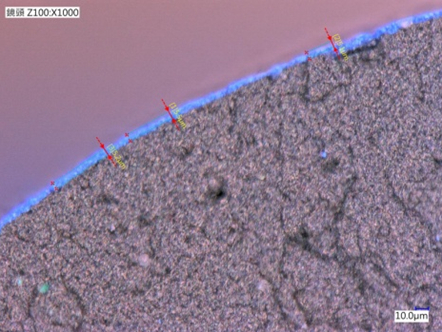

GMORS equip ourselves with advanced instruments for the most accurate analysis to the properties of sealing parts. One of them is the high resolution microscope which enables us to access to surface details after coating process. Including measuring thickness of coating layer, surface roughness or some other microscopic inspection, this in-house facility give us a quick and actual view before/after surface treatment to seals.

Coating thickness was measured as shown in Figure 7. Cross section of product must be specially processed to keep original coating shape for precise thickness measurement by microscope. High magnification is needed to measure/observe a micron-thick coating layer.

Sign up for GMORS latest news.

Copyright ©GE MAO RUBBER INDUSTRIAL CO., LTD. All rights reservedTerms and Conditions|Privacy policy