O-Ring, the cutting edge is a "O" shape, which is the most common, classic, economical and useful sealing type in both dynamic and static application.

To understand a basic idea of O-Ring,it is essential you should know:

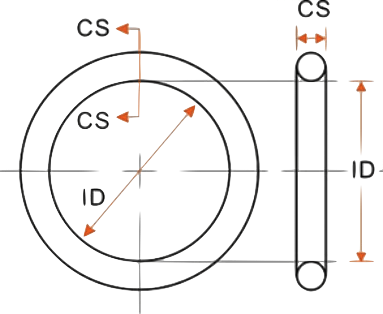

- The O-Ring dimension formula is very simple, OD = ID + 2*CS

- The popular O-Ring standards are formulated by its location and country

- The O-Ring tolerance has its limitation, when the size is out of tolerance; it means failure will cause leakage.

- O-Rings are made of elastomers which are with resilience or memory sufficient to return to its original shape after a major or minor distortion

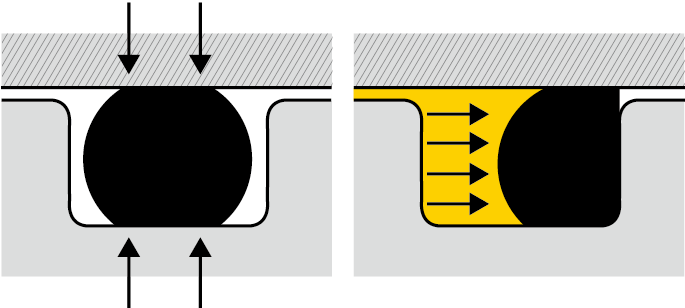

How an O-Ring behave its sealing function:

|

|

|---|---|

| Compression of the O-Ring-filling the gap | Pressure activation of the O-Ring |

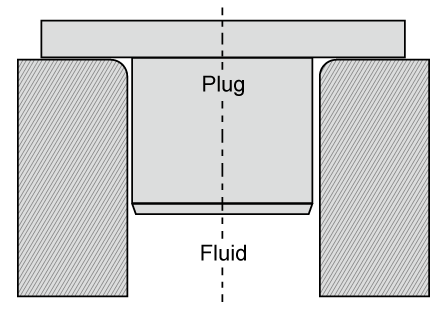

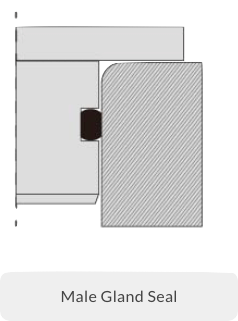

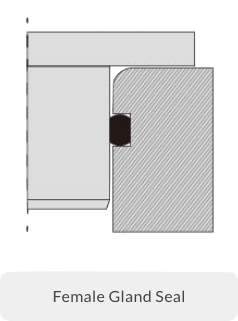

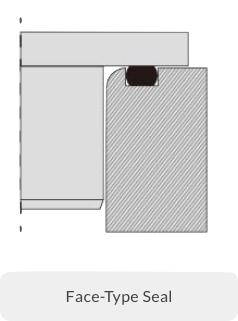

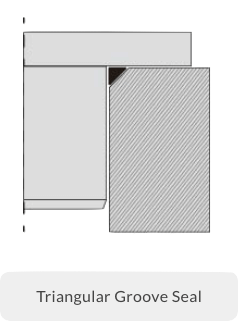

In terms of the assembly aspect, in general O-Ring can be selected in four sealing types :

Quality and service is not ruled by a voice or written of many, it is something when you use it, and you know it.

There are thousands of O-Ring manufacturers worldwide, and it's not easy to find a suitable supplier. GMORS want to bring you another section to get far away of Red Ocean and approach Blue Ocean with us.

What value can GMORS offer?

- Various international O-Ring standards, most sizes are already tooling which you don't need to invest.

- Suitable and well known raw material suppliers to guarantee the product basic quality.

- Certificated compound to meet specific markets.

- Certificated laboratory to develop and identify match compound per your specification or ASTM D200 call out.

- Wide range of O-Ring hardness from 40 to 95 duro, GMORS both offer compound to meet Shore A & IRHD according to your need.

- Accurate tool house technology to create tools for high quality production

- External Lubricants & Coatings on O-Ring surface for your assembly (PTFE coating, Silicone fluid, MoS2, talcum powder, Silicone polymer based coating).

- Well O-Ring surface especially in parting line.

- Except general industry, GMORS provide strict production control in CPK/PPK in specific markets.

- Full ranges of standard O-Ring stock which to decrease the waiting of long lead time, and best online stock system for searching and ordering for our formal customers.

- The most convenient O-Ring Master APP to help you find ideal dimension and material.

FEATURES

Full standard O-Ring series: AS 568, BS 4518, GB/T 3452.1, JIS B2401 P/G/S/V, SMS 1586 , METRIC and JASO F404.

BENEFITS

Smallest 0.5mm (ID) × 0.4mm (CS)

Largest 1600mm (ID) × 50mm (CS)